DESIGN

Our mechanical engineering office specializes in creating individual device designs and technical solutions for new products that precisely meet your specific requirements and needs, turning your visions into a real product.

Our aim is to design the products for your business

to make sure your visions will turn into reality.

We can ensure the complete development,

production and delivery of your new product

and save your costs associated

with the renting of the CAD system licenses.

Our mechanical engineering office specializes in creating individual device designs and technical solutions for new products that precisely meet your specific requirements and needs, turning your visions into a real product.

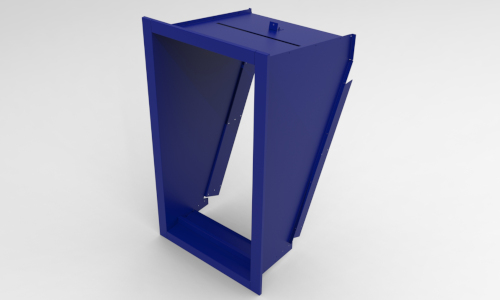

Detailed 3D models are created based on the agreed designs using professional software Creo Parametric, enabling us to identify potential problems before production and to optimize the manufacturing process, whether it's for routine or more complex projects.

Complete production documentation is created in digital formats such as PDF, DXF, DWG, STL, and others. This process involves thorough processing and data conversion tailored to the specifics of each format, ensuring optimal conditions for production and compatibility with various manufacturing technologies and devices.

Even before the start of the production, we can create realistic visualizations of the device and, using augmented reality (AR), show you the final product in accurate details as if it were right in front of you. Using a tablet or phone, you can see your new product in a real environment.

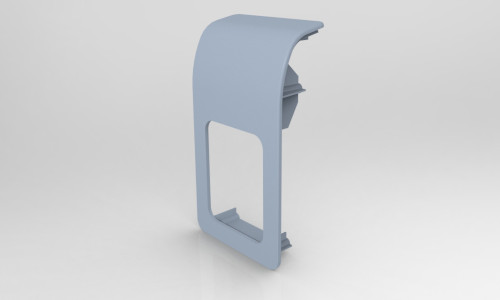

Before 3D printing, model preparation is ensured, including geometry optimization. We prefer the HP JET FUSION 3D printing technology, allowing us to achieve high precision, consistent shape, and smooth surface of the final part at affordable costs.

Electronics and programmable functions allows you to control your product easily and intuitively. We will create a custom-designed printed circuit board that not only ensures optimal functionality but also adds uniqueness to your new product, emphasizing its individuality and value.

We offer our customers comprehensive services in the field of prototype manufacturing. We thoroughly test the devices, allowing us to improve and refine them even before starting serial production.

We ensure serial production of the devices or components starting from one piece. We will arrange assembly, varnishing and delivery. We consistently pay attention to the final quality of the product.

Transport of your products will be provided with careful respect to the agreed deadlines.

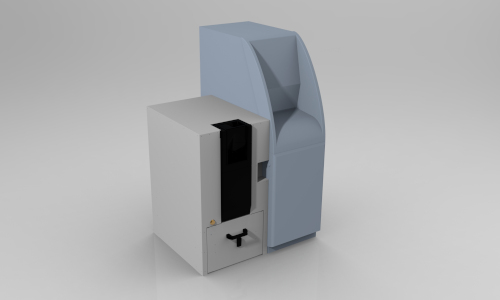

A big challenge for us was the design and subsequent production of a coffee roaster...

Read More

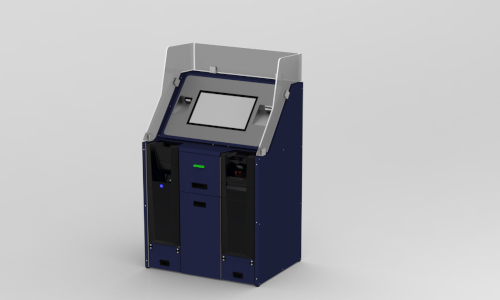

The added value of this self service payment kiosk lies in the rotating carousel that pours coins into…

Read More

Thanks to this coin self payment kiosk, a sufficient amount of...

Read More

The assignment was to connect banknote and coin recycling machines into a secure...

Read More

Our customer needed to vividly imagine the concept of a self-service kiosk...

Read More

The scientific team of the Department of Plant Physiology of the Faculty of Natural Sciences of Charles University needed special...

Read More

This self service payment kiosk is used for receiving and issuing banknotes and...

Read More

"Mr. Kizek was designing a part from a powder 3D printer for us. The part was delivered on time and at an affordable price."

"We have been cooperating with the Kizek company for a long time to expand our product portfolio. Thanks to the quick development of new devices, we are always one step ahead of the competitors."

"In an effort to find a suitable roaster machine for our roaster, we went through quite a large selection, but with each of them we came across restrictions or limits that would significantly limit us when roasting coffee and maintaining the roaster itself. With this challenge, we approached the mechanical engineering office Kizek, which was able to provide us a complete service related to the development and production of a roaster exactly according to our specific requirements. In addition, the Kizek company brought its design and technological know-how to the process, enabling the creation of a compact and unique coffee roaster. Through this new roaster, we are able to achieve absolutely exceptional pure coffee flavors that would otherwise be impossible to achieve. Important maintenance and ensuring the hygiene of the roaster is very easy and time-saving thanks to the materials used and easy access to all parts."

"Mr. Kizek developed several projects for us according to our requirements, which were completed successfully and on time. We have established permanent cooperation with Kizek company."